In 2010 I have been hired by Saint Gobain at Maintenance department, because their automation engineer left the company.

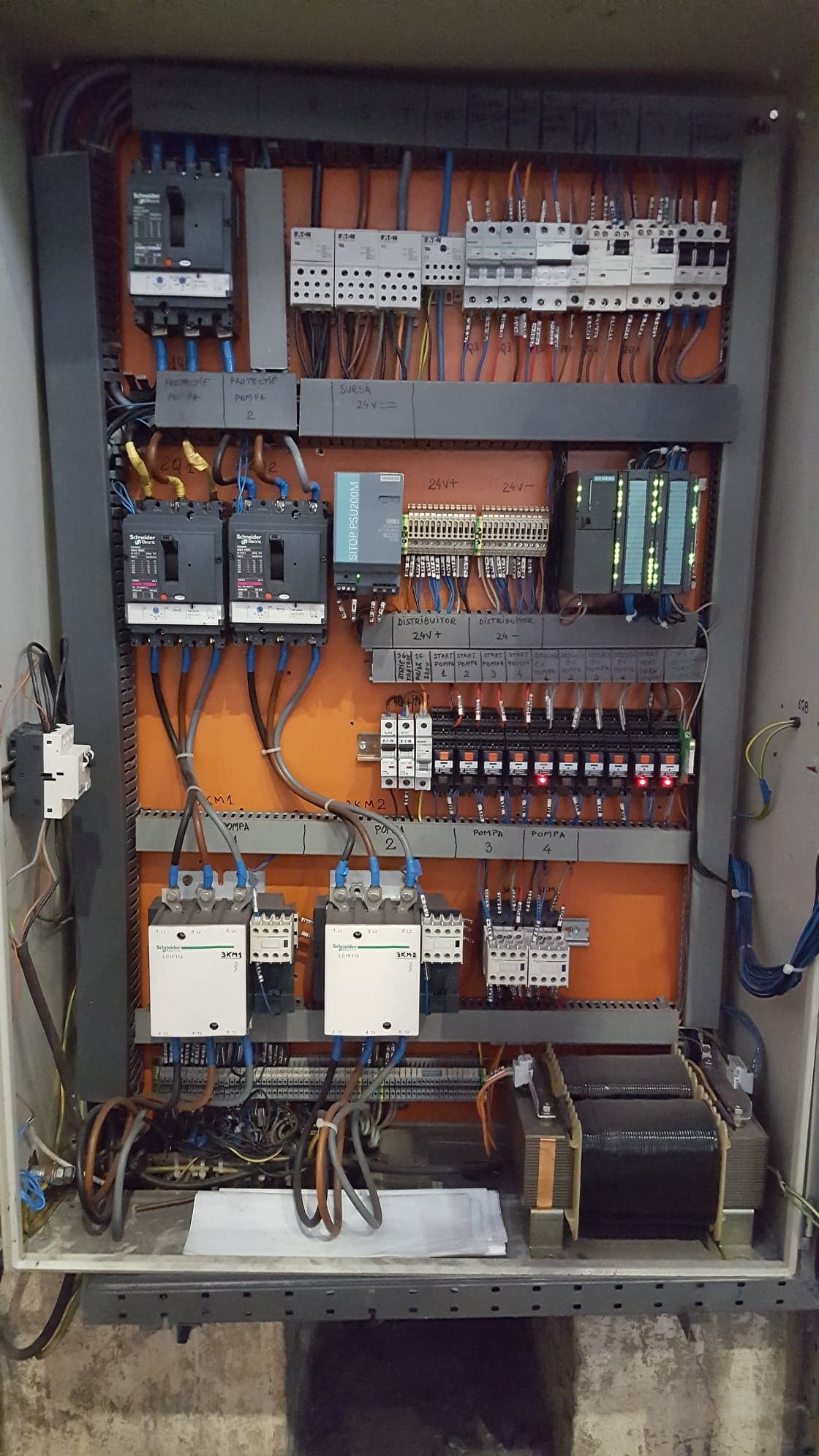

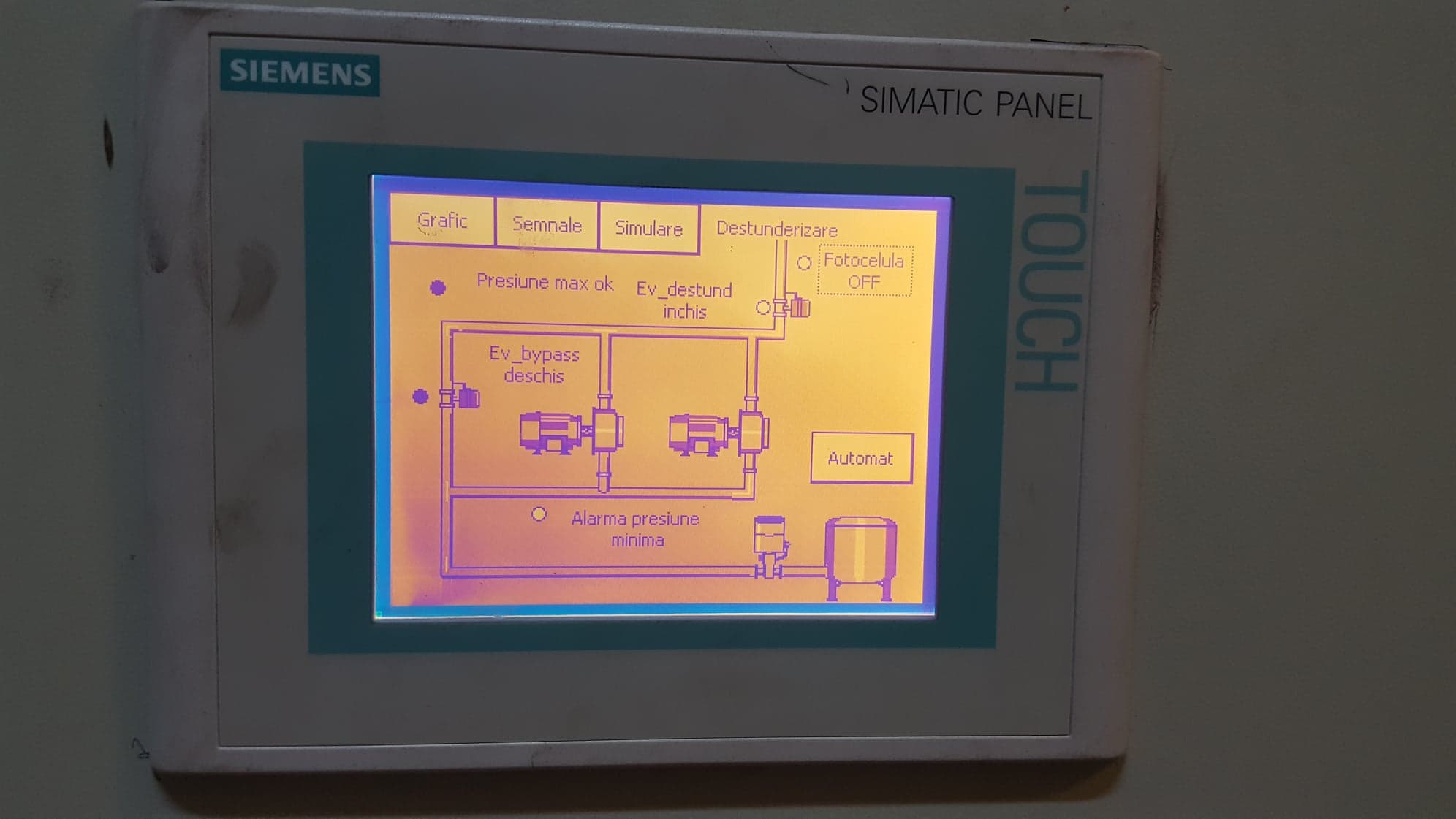

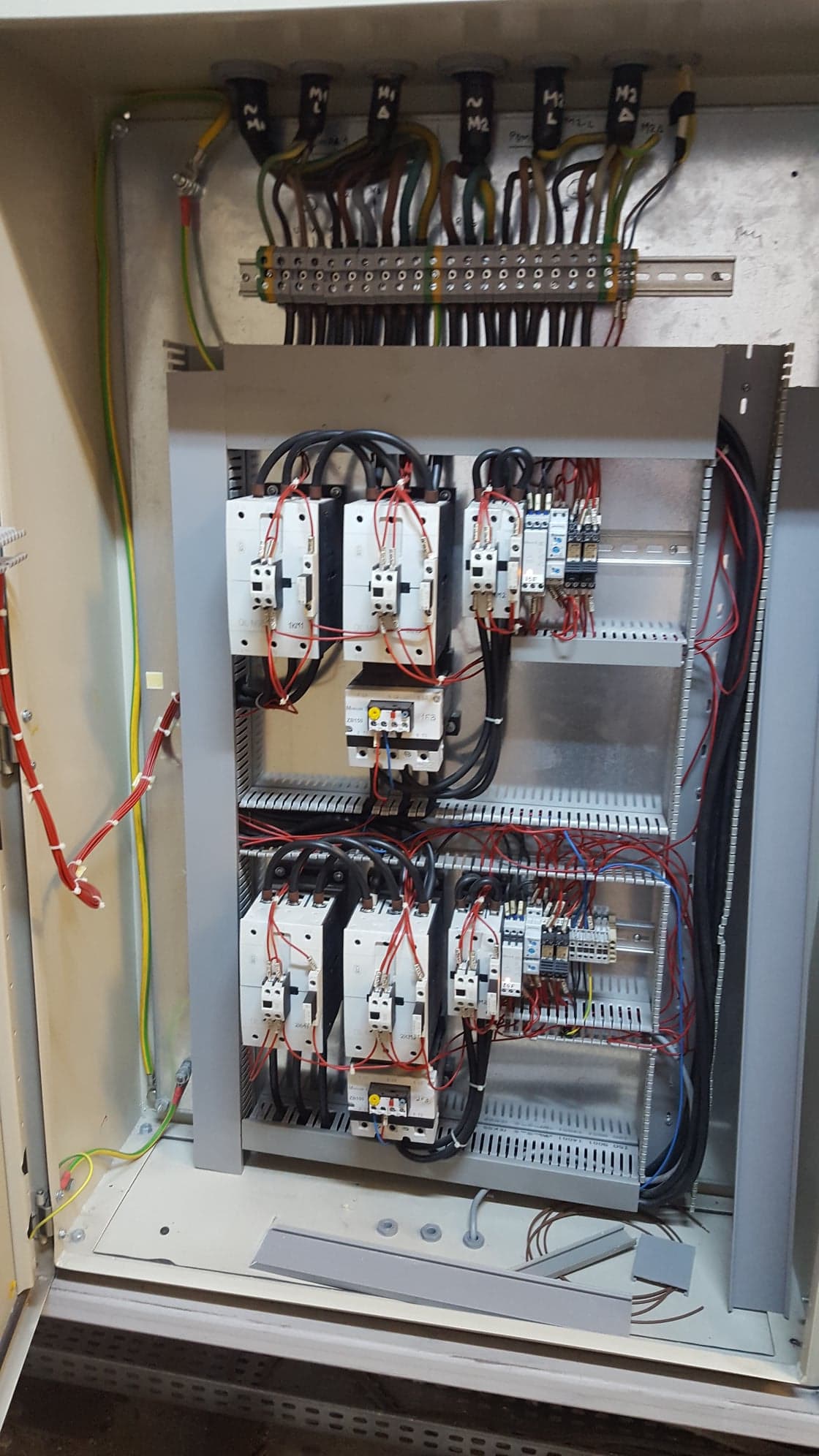

In the first 3 months I have been trained on DCS automation system (Yokogawa). After one year and a half, the maintenance manager left, and the responsible engineer for the measurement and control devices became maintenance manager. I have been promoted to his place and I started to learn more about sensors (inductive, temperature, pressure, level and distance), flow meters for gas/ water, and signal converters. There was also an osmosis system controlled by Siemens S300 PLC and half of the production line controlled by Siemens S400. I had there one colleague on automation who made Siemens course, and he started to teach me about Siemens PLC.